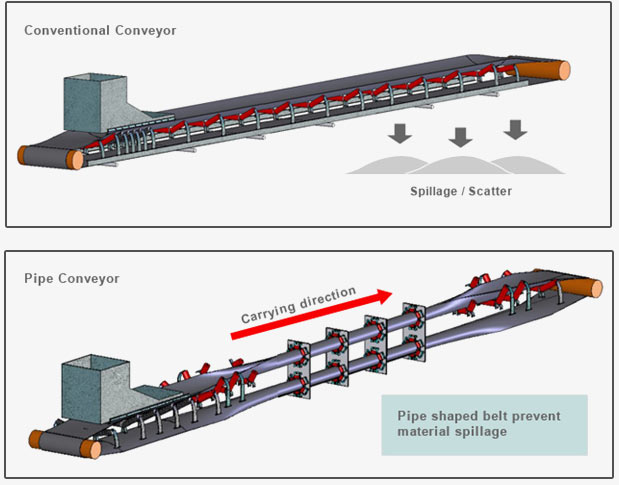

Pipe or Tube conveyor belts are primarily used where bulk materials must be conveyed along horizontal and vertical curves in confined spaces, and/or where the environment has to be protected resp. where spillage must be avoided.

The belt can negotiate tight horizontal and vertical curves. This eliminates or reduces transfer points, which is a big cost saving. Inclinations of up to 35° can be dealt with.

Pipe conveyor belts protect the conveyed material from external influences like rain and wind and protect the environment by avoiding spillage of the conveyed material. Even in the bottom run, no spillage will occur, because the carry side is inside of the tube. The idler supports can be spaced farther apart, because it is self-supporting. An additional conveyor cover is not necessary.

Some of the salient features of Pipe Conveyor Belts

- Dust and spillage free transportation

- Low noise emissions

- Inclines up to 35°

- Multiple feed and discharge points

- Simultaneous conveying of different materials in both directions

- Low power consumption

- Horizontal and vertical curves with radii to 45 metres

| TECHNICAL INDEXES | ||||||

|---|---|---|---|---|---|---|

|

Pipe dia. |

Load area |

Belt speed |

Conveying |

Max. lump |

Horizontal |

Equivalent |

|

100 |

0.006 |

100 |

36 |

30 |

15 |

300 |

|

150 |

0.013 |

120 |

95 |

30-50 |

18 |

300-450 |

|

200 |

0.024 |

130 |

185 |

50-70 |

20 |

500-600 |

|

250 |

0.037 |

140 |

310 |

70-90 |

23 |

600-750 |

|

300 |

0.052 |

150 |

475 |

90-100 |

25 |

750-900 |

|

350 |

0.072 |

175 |

750 |

100-120 |

30 |

900-1050 |

|

400 |

0.095 |

200 |

1140 |

120-150 |

35 |

1050-1200 |

|

450 |

0.150 |

225 |

2000 |

150-200 |

50 |

1500-1800 |

|

500 |

0.215 |

250 |

3200 |

200-250 |

50 |

1500-1800 |

|

550 |

0.285 |

275 |

4700 |

250-300 |

60 |

1800-2000 |

|

600 |

0.425 |

300 |

7650 |

300-400 |

70 |

2000-2400 |