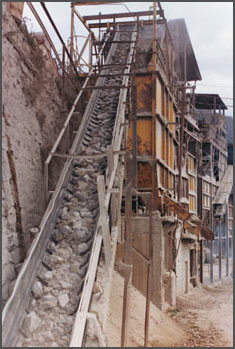

Continental Chevron Conveyor Belts are designed for space-saving on steep inclines, even up to 40 Degrees, where they deliver increased capacity when carrying bulk materials with a lump size up to 150mm, used in varied applications, such as stone, sand, fertiliser, coal, coke clinkers, potatoes, etc.

Features

- Excellent choice for high capacity conveying at steep angles to prevent load slip or product roll back

- Cleats integrally moulded with the top cover rubber preventing separation from the belt

- A large range of designs and patterns available

- Cleats with high abrasion resistance and elastic rubber compounds for flexibility

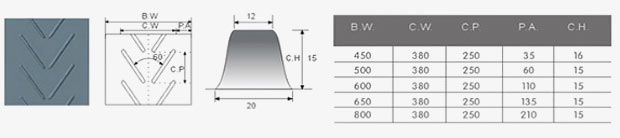

- Various cleat heights and widths available depending on the application requirements

- Unique Pattern design ensures, that, the belt has a smooth run on conventional return idlers, so no modification of the conveyor required. A smooth transition from a conventional flat belt to a Chevron belt can be implemented.

- Chevron belts manufactures, in all cover grades, viz. Abrasion Resistant M24, HR, OR, FR, White Hygienic, etc.

Some of the Key Applications:

- Wood Chips

- Sand and Gravel

- Heavy Duty Scrap Metal

- Minerals – Coal and Ore

- Materials – Fine Coal and Grains

- Waste and Recycling Plants

- Road Construction & Crushing Industries

- Bagged Materials

- Steel Pellets